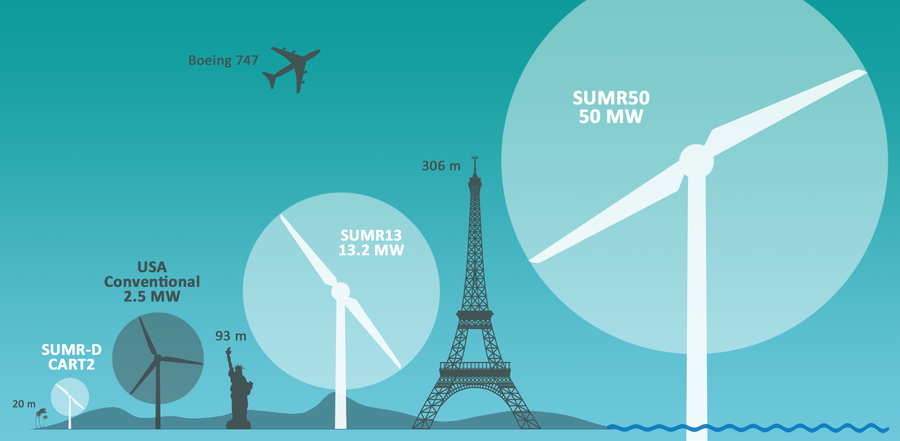

Wind energy is soaring in the U.S.; the nation’s renewable energy capacity has more than tripled in the past nine years, and wind and solar power are largely responsible. Now businesses want to harness even more wind energy, at a cheaper price—and one of the best ways to lower cost is to build bigger turbines. That’s why an alliance of six institutions led by researchers at the University of Virginia are designing the world’s largest wind turbine at 500 meters tall—almost a third of a mile high, and about 57 meters taller than the Empire State Building.

Turbines are already noticeably larger than they were 15 or 20 years ago. Size varies, but today’s typical wind farm towers stand around 70 meters tall, with blades about 50 meters long. Their power output depends on size and height, but it generally ranges between one and five megawatts—on the upper end, that’s enough to power about 1,100 homes. “There's this motivation to go to larger wind turbines, and the reason is pretty much economics,” explains John Hall, an assistant professor of mechanical and aerospace engineering at the University at Buffalo, S.U.N.Y. One reason giant turbines are more cost-effective is that wind blows stronger and more steadily at greater altitudes. Thus, “you capture more energy” with a taller structure, says Eric Loth, project leader of the massive turbine project, which is funded by the U.S. Department of Energy’s Advanced Research Projects Agency–Energy (ARPA–E).

Another reason wind experts say bigger is better: longer turbine blades also catch the wind more efficiently, and taller towers enable lengthier blades. A turbine’s power is directly related to its “swept area”—the circular area covered by the blades’ rotation—explains Christopher Niezrecki, a professor of mechanical engineering and director of the Center for Wind Energy at the University of Massachusetts Lowell. And this relationship is not linear—if blade length doubles, a system can produce four times as much energy, Niezrecki explains. He notes that bigger turbines also have a lower “cut-in” speed, the wind speed at which they can start generating energy.

On supporting science journalism

If you're enjoying this article, consider supporting our award-winning journalism by subscribing. By purchasing a subscription you are helping to ensure the future of impactful stories about the discoveries and ideas shaping our world today.

Loth’s team wants to design a 50-megawatt system with blades 200 meters long, much larger than today’s wind turbines. If the researchers succeed, they believe the turbine would be 10 times more powerful than existing equipment. But the scientists do not intend to simply supersize conventional designs; they are fundamentally changing the turbine structure. The ultralarge machine will have two blades instead of the usual three, lowering the weight of the structure and cutting costs.Loth says that reducing the number of blades would ordinarily make a turbine less efficient, but his team is using an advanced aerodynamic design that he says largely makes up for those losses.

Concept of SUMR project. Credit: Chao Qin

The team also envisions these gigantic structures standing at least80 kilometers offshore, where winds tend to be stronger and where people on land cannot see or hear them, according to Loth. But powerful storms hit such places—off the U.S. east coast in the Atlantic Ocean, for example—so Loth’s team faced the quandary of creating something massive that is also relatively lightweight and still resilient in the face of hurricanes. To tackle the problem, the researchers looked to one of nature’s own design solutions: palm trees. “Palm trees are really tall but very lightweight structurally, and if the wind blows hard, the trunk can bend,” Loth says. “We’re trying to use the same concept—to design our wind turbines to have some flexibility, to bend and adapt to the flow.”

In the team’s design the two blades are located downwind of the turbine’s tower, rather than upwind as they are on traditional turbines. The blades also change shape with the wind’s direction, similar to a palm tree. “When the blades bend back at a downwind angle, you don’t need to build them as heavy or strong, so you can use less material,” Loth explains. This design also lessens the possibility that strong winds will bend a spinning blade toward its tower, potentially knocking the whole structure down [Video]. “The blades will adapt to high speeds and start to fold in, so there are less dynamic forces on them,” Loth says. “We’d like our turbines to be able to handle higher than 253-kilometer-per-hour winds” in nonoperating conditions.Above a wind speed of 80 to 95 kilometers per hour the system would shut down and the blades would bend away from the wind, so they could withstand violent gusts, Loth adds.

The 500-meterturbine still faces challenges—there are good reasons no one has yet built one close to this size: “How do you make 200-meter blades? How do you put them together? How do you erect such a tall tower? Cranes only go so high. And with offshore wind, [there are] additional complications,” Niezrecki says. The team’s design includes a segmented blade that could be assembled from pieces on site, but Niezrecki notes the wind industry has not quite figured out how to segment the blades just yet. “There are lots of research questions to be addressed,” he says. “It’s definitely high risk, but there’s also potential for high reward as well. I don’t think those problems are insurmountable.” Hall also questions whether such a massive turbine is the optimal size. “We are figuring out that bigger is better. The question is, how much bigger? We need to find that sweet spot,” he says. “We’re going to learn a lot from this project.”

Loth and his team have yet to test a prototype; they are currently designing the turbine’s structure and control system, and this summer they are building a model much smaller than the real thing—about two meters in diameter. Next summer they plan to construct a larger version with two 20-meter-long blades, which will produce less than a megawatt of power and will be tested in Colorado. Loth himself is not 100 percent certain his team’s mammoth turbine will become a reality but he is sure it is worth trying. “This is a very new concept, so [there are] definitely no guarantees it will work,” he says. “But if it does, it will revolutionize offshore wind energy.”